Understanding the Different Types of Valve Products

- Mark Richardson

- Jun 24, 2025

- 4 min read

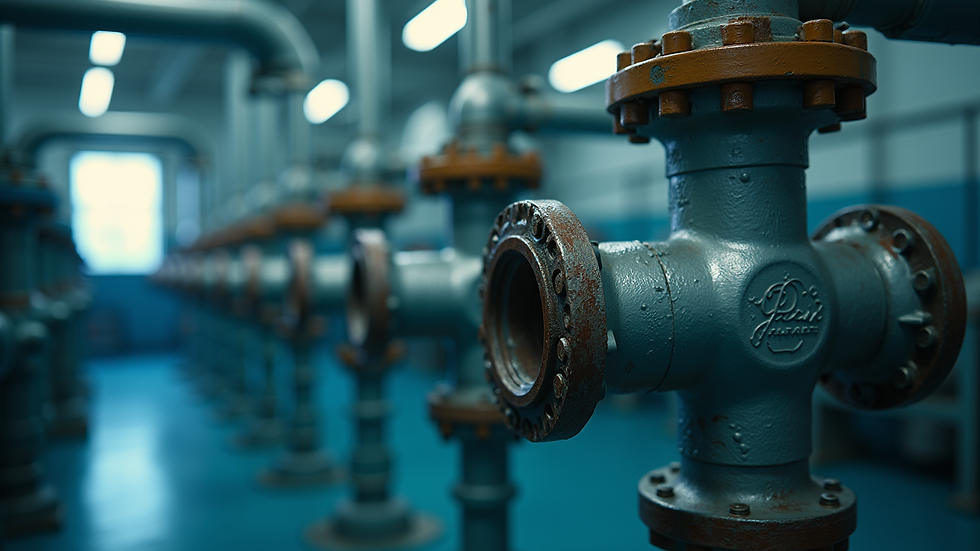

Valves are essential components in various industries, playing a significant role in controlling the flow of liquids, gases, and other materials. With the diverse array of valve products available, understanding the different types and their applications can help you make informed decisions for your projects. In this post, we will explore several common types of valve products, their features, and their applications.

Overview of Valve Products

Valves are mechanical devices designed to control, direct, or regulate the flow of fluids. They are widely used in applications ranging from plumbing and water management to industrial processes and HVAC systems. Valves can be classified based on their operation, design, and intended use.

Some key factors to consider when choosing a valve include:

Flow Direction: The way fluid flows through the valve.

Control Mechanism: How the valve is operated (manual, automated, etc.).

Material: The substance from which the valve is made, impacting durability and compatibility with various fluids.

Types of Valve Products

There are several types of valves, each designed for specific purposes. Below is a brief overview of some of the most common valve products:

Ball Valves

Ball valves are widely used due to their durability and ability to maintain a tight seal. They operate using a spherical disc that rotates to open or close the flow path. Ball valves are best for on-off control in applications where quick shut-off is necessary. They come in different materials, including brass, stainless steel, and plastic, making them versatile for various environments.

Applications: Water supply systems, gas pipelines, and industrial fluid control.

Advantages: Quick operation and minimal pressure drop.

Gate Valves

Gate valves are designed for completely opening or closing a flow path, rather than regulating flow. They use a wedge-shaped gate that moves up and down to control the flow. These valves are typically used in applications where minimal pressure drop is essential.

Applications: Wastewater management, fire protection systems, and irrigation.

Advantages: Low flow resistance and high durability.

Check Valves

Check valves allow fluid to flow in only one direction, preventing backflow. They rely on the pressure of the fluid to open and close rather than requiring external force. There are several designs, including swing check valves and lift check valves, each with its unique advantages depending on the specific application.

Applications: Pumps, pipelines, and HVAC systems.

Advantages: Protects equipment from damage caused by backflow and can help maintain system pressure.

Globe Valves

Globe valves are primarily designed for regulating flow rather than completely shutting it off. They have a spherical body design, which offers a larger surface area for regulating flow. This feature makes them ideal for applications requiring precise control.

Applications: Water treatment plants, heating systems, and process control applications.

Advantages: Excellent flow regulation capabilities.

Butterfly Valves

Butterfly valves consist of a rotating disc that is mounted on a shaft. When the valve is turned, the disc rotates to either allow or restrict flow. They are particularly useful in applications requiring quick operation and are available in various materials and sizes, including the popular 4 inch butterfly valve.

Applications: HVAC and fire protection systems, food processing, and water distribution.

Advantages: Lightweight, compact, and cost-effective.

How to Choose the Right Valve

Choosing the right valve for your application involves analyzing several factors. Here are some key considerations to keep in mind:

Pressure and Temperature Ratings: Ensure the valve can handle the specific pressure and temperature of your application to avoid failure.

Material Compatibility: Consider the fluid that will flow through the valve and choose materials that minimize corrosion and wear.

Space Constraints: Assess the available space for installation and select a valve that fits appropriately.

Control Requirements: Determine if you need a valve for precise flow regulation or one for on-off control.

It's generally a good idea to consult with industry experts or suppliers for advice on the best valve types for your specific needs.

Maintenance of Valves

Regular maintenance of valves is crucial for ensuring their reliability and longevity. Here are some actionable recommendations for maintaining valve products:

Inspection: Regularly inspect valves for leaks, rust, or other signs of wear.

Lubrication: Some valves require lubrication to ensure smooth operation, particularly those with moving parts.

Cleaning: Clean valve components regularly to prevent build-up of debris and corrosion.

Testing: Conduct pressure tests to ensure valves are functioning correctly, especially in critical applications.

Maintaining your valves helps prevent unexpected failures and reduces overall costs associated with repairs and replacements.

Summary of Valve Product Types

Understanding the different types of valve products is essential for anyone involved in fluid management or system design. From ball and gate valves to globe and butterfly valves, each type serves a unique purpose and has distinct advantages. Make sure to consider your specific requirements, such as pressure, temperature, and flow direction, when selecting a valve.

The right valve can improve the efficiency and reliability of your systems, leading to smoother operations and reduced downtime. Don't hesitate to consult with professionals for tailored advice based on your application needs.

Comments