Understanding the Benefits of Butterfly Valves for Industrial Use

- Mark Richardson

- Aug 12, 2025

- 4 min read

Butterfly valves are essential components in many industrial systems. They control the flow of liquids, gases, and slurries efficiently and reliably. These valves are known for their simple design, ease of operation, and cost-effectiveness. In this article, we will explore the key benefits of butterfly valves, their applications, and why they are a preferred choice in various industries.

What Are Butterfly Valves and How Do They Work?

Butterfly valves consist of a circular disc or vane mounted on a rotating shaft inside a pipe. When the valve is fully closed, the disc blocks the flow. When it is fully open, the disc is rotated a quarter turn to allow flow through the pipe. The valve can also be adjusted to regulate flow at any position between fully open and fully closed.

The design is compact and lightweight compared to other valve types like gate or ball valves. This makes butterfly valves easier to install and maintain. The disc’s rotation provides quick operation, which is crucial in many industrial processes.

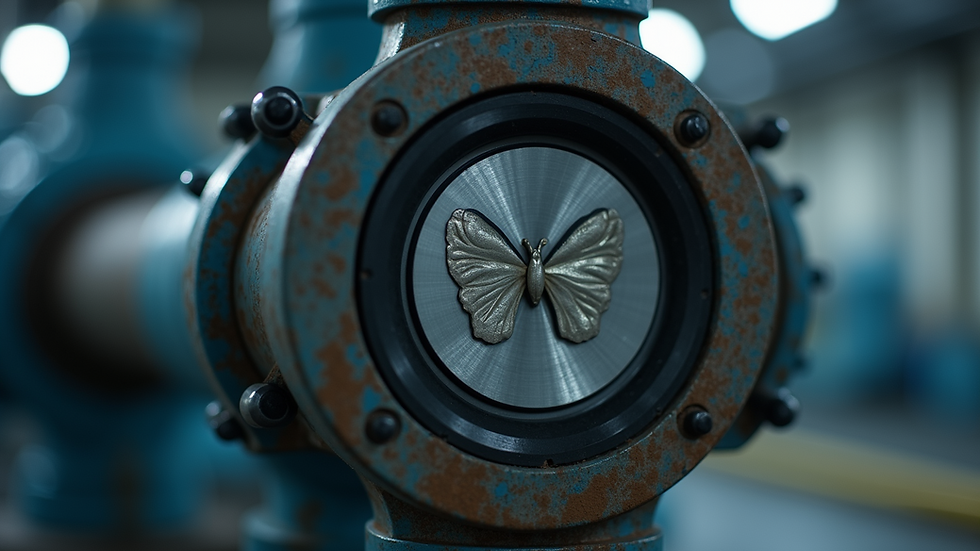

Close-up view of butterfly valve disc inside a pipeline

Key Benefits of Butterfly Valves in Industrial Applications

Butterfly valves offer several advantages that make them ideal for industrial use:

Compact and Lightweight Design: Their slim profile reduces the space needed for installation. This is especially beneficial in plants with limited room.

Cost-Effective: Butterfly valves are generally less expensive than other valve types, both in initial cost and maintenance.

Quick Operation: The quarter-turn mechanism allows fast opening and closing, which is important for emergency shut-offs or flow adjustments.

Versatility: Suitable for a wide range of fluids including water, air, chemicals, and slurries.

Low Pressure Drop: When fully open, the disc offers minimal resistance to flow, reducing energy consumption.

Durability: Made from robust materials, butterfly valves can withstand harsh industrial environments.

For example, in water treatment plants, butterfly valves regulate water flow efficiently while resisting corrosion. In chemical processing, they handle aggressive fluids safely with appropriate lining materials.

Eye-level view of industrial butterfly valve installed on a large pipeline

Choosing the Right Butterfly Valve for Your Industry

Selecting the correct butterfly valve depends on several factors:

Material Compatibility: The valve body and disc materials must resist the fluid’s chemical properties. Common materials include stainless steel, cast iron, and various plastics.

Size and Pressure Rating: Valves come in different sizes and pressure classes. Ensure the valve matches your system’s specifications.

Type of Actuation: Butterfly valves can be manually operated, or automated with electric, pneumatic, or hydraulic actuators.

Sealing Mechanism: The valve seat and seal type affect leak tightness and durability. Soft seats provide better sealing but may have temperature limits, while metal seats handle higher temperatures.

Installation Requirements: Consider space constraints and connection types such as wafer, lug, or flanged.

For instance, a 4 inch butterfly valve with a stainless steel body and EPDM seat is a popular choice for water and wastewater applications due to its corrosion resistance and reliable sealing.

Practical Applications of Butterfly Valves in Industry

Butterfly valves are widely used across many sectors:

Water and Wastewater Treatment: Control flow in pipelines, tanks, and filtration systems.

Oil and Gas: Manage crude oil, natural gas, and refined products in pipelines and processing plants.

Chemical Processing: Handle corrosive and hazardous fluids safely.

Food and Beverage: Sanitary butterfly valves ensure hygienic flow control.

HVAC Systems: Regulate air and water flow in heating and cooling systems.

Power Generation: Control steam, cooling water, and fuel flow.

Their ability to provide reliable shut-off and flow regulation makes them indispensable in these industries. For example, in HVAC systems, butterfly valves help maintain temperature control by adjusting water flow through heat exchangers.

High angle view of butterfly valve in a chemical processing plant

Maintenance Tips to Maximise Butterfly Valve Lifespan

Proper maintenance ensures butterfly valves perform optimally and last longer. Here are some practical tips:

Regular Inspection: Check for leaks, corrosion, and wear on the disc and seat.

Clean the Valve: Remove debris and buildup that can affect sealing and operation.

Lubricate Moving Parts: Apply suitable lubricants to the shaft and bearings to reduce friction.

Test Operation: Cycle the valve periodically to prevent sticking.

Replace Worn Components: Seats and seals may need replacement over time to maintain tight shut-off.

Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules and procedures.

By following these steps, industries can avoid costly downtime and extend the service life of their butterfly valves.

Why Butterfly Valves Are a Smart Investment for Industry

Investing in butterfly valves offers long-term benefits:

Reduced Installation and Maintenance Costs: Their simple design lowers labour and material expenses.

Energy Efficiency: Minimal pressure drop saves energy in pumping systems.

Improved Process Control: Quick and precise flow regulation enhances operational efficiency.

Reliability and Safety: Durable construction and tight sealing reduce the risk of leaks and accidents.

Wide Availability: Butterfly valves are readily available in various sizes and materials to suit any industrial need.

Choosing the right butterfly valve can improve system performance and reduce operational costs, making it a smart choice for industrial applications.

Butterfly valves combine simplicity, efficiency, and versatility, making them indispensable in many industrial settings. Whether you need to control water flow in a treatment plant or manage chemicals in a processing facility, butterfly valves provide reliable and cost-effective solutions. By understanding their benefits and proper maintenance, you can ensure your industrial systems operate smoothly and efficiently for years to come.

Comments