Understanding How Butterfly Valves Work in Industrial Systems

- Mark Richardson

- Jul 1, 2025

- 4 min read

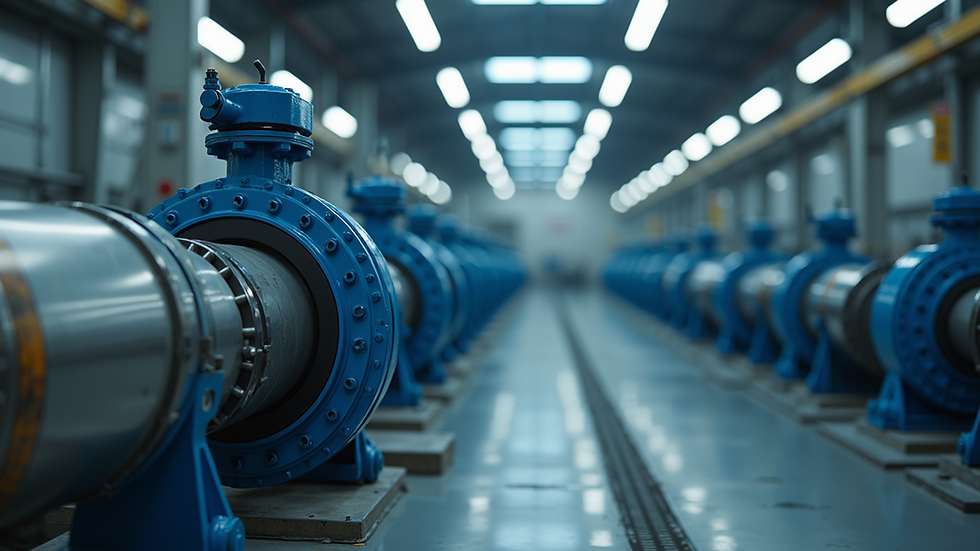

Butterfly valves are essential components in various industrial systems, providing an efficient way to manage the flow of liquids and gases. Their simplicity, durability, and compact design make them an attractive choice for engineers and operators alike. In this blog post, we'll explore how butterfly valves work, their applications in industrial systems, and some best practices for selection and maintenance.

What are Butterfly Valves?

Butterfly valves are quarter-turn valves that use a circular disc to control the flow of fluid. When the handle or actuator is turned, the disc rotates to either fully block or allow the flow of media through the valve. Their design allows for quick operation and minimal pressure drop, making them ideal for a range of applications from water supply systems to chemical processing plants.

One key advantage of butterfly valves is their lightweight construction, which makes installation easier and reduces the overall load on pipes. They can be made from various materials such as cast iron, stainless steel, and plastic, depending on the media being controlled and the operating conditions.

How Do Butterfly Valves Function?

Butterfly valves operate on a simple mechanism. The basic parts of a butterfly valve include the body, a disc (or plate), a shaft, and the actuator. When the valve is open, the disc is parallel to the flow direction. Conversely, when closed, the disc obstructs the flow path.

Components of a Butterfly Valve

Body: This is the main component that houses all other parts. It's designed to withstand pressure and corrosion, depending on the application.

Disc: The disc is the essential moving part that determines whether the valve is open or closed. It is usually round and rotates around an axis.

Shaft: Connected to the disc, the shaft transmits motion from the actuator to the disc.

Actuator: The actuator can be manual (like a handwheel) or automated (like an electric or pneumatic actuator). This device controls the position of the disc.

Understanding how these components work together is crucial for assessing the performance and durability of a butterfly valve in an industrial setting.

Applications of Butterfly Valves

Butterfly valves are widely used in various industries, including:

Water Treatment: Butterfly valves control the flow and pressure of water in treatment plants, helping to regulate the distribution of clean water.

Oil and Gas: In pipelines transporting crude oil and natural gas, butterfly valves manage flow rates and protect against leaks.

Food and Beverage: These valves are often applied in food processing due to their hygienic design, ensuring minimal contamination risk.

Chemical Industry: Butterfly valves provide a reliable solution for handling aggressive chemicals, thanks to their ability to resist corrosion.

One specifically useful size in various applications is the 4 inch butterfly valve, which is common in many piping systems due to its flexible size and high performance.

Advantages of Using Butterfly Valves

Space Efficiency: Their compact design allows for easier installation in tight spaces compared to other valve types.

Cost-Effective: Generally, butterfly valves are more affordable than other types of valves, which helps in reducing overall project costs.

Low Pressure Drop: Their design minimizes turbulence when fluid passes through, resulting in a reduced pressure drop across the valve.

High Performance: Quick and easy operation ensures that they can adjust fluid flow efficiently.

These advantages make butterfly valves a go-to choice for engineers looking for reliable flow control in a wide range of industrial applications.

Best Practices for Selection and Maintenance

Selecting the right butterfly valve for your application and maintaining it properly is essential for optimal performance. Here are some best practices:

Selection Criteria

Material Compatibility: Choose a valve material that can withstand the properties of the fluid, such as temperature, pressure, and chemical composition.

Size: Ensure the valve is appropriately sized for the pipeline system. The right size will prevent issues such as excessive pressure loss or flow obstructions.

Actuation Type: Decide on manual or automatic actuation based on your system requirements. Automatic actuators may be necessary for remote or critical operations.

Maintenance Tips

Regular Inspection: Periodically check for wear and tear, leaks, or corrosion. This early detection can prevent larger issues down the line.

Lubrication: Ensure that the actuator and shaft are well-lubricated to maintain smooth operation and reduce wear.

Cleanliness: Keep the valve clean and free of debris. Contaminants can affect performance and lifecycle.

By adhering to these selection and maintenance practices, you can ensure that your butterfly valves work efficiently and last longer in your industrial systems.

The Future of Butterfly Valves in Industry

As technology evolves, so do the designs and functionalities of butterfly valves. Innovations are continuously integrated into their manufacturing, enhancing performance, durability, and ease of use. For instance, smart valves equipped with sensors can provide real-time data on flow rates and potential issues, offering predictive maintenance opportunities.

In addition, advancements in materials science are leading to the development of lightweight yet robust materials that can handle more extreme conditions, expanding the application potential for butterfly valves in industries like aerospace and cryogenics.

These future advancements not only improve the efficiency of butterfly valves themselves but also increase the overall efficiency of industrial systems.

Understanding how butterfly valves work and their role in industrial systems is fundamental for anyone involved in fluid control. By selecting high-quality valves, applying best practices for maintenance, and staying abreast of technological advancements, industries can ensure optimal performance and reliability in their operations. Whether you're working in water treatment, oil and gas, or manufacturing, butterfly valves prove to be invaluable.

Comments